How Lightweight Materials Are Making Cars Safer, Cheaper, and Greener

For decades, American drivers have prioritized power and space in their vehicles—but a quiet revolution is underway under the hood. Lightweight materials are reshaping the automotive industry, offering a triple threat of benefits: safer rides, lower costs, and a greener planet. While steel has long dominated car manufacturing, innovations in materials science are redefining what cars can be.

Related searches

Stronger Doesn't Mean Heavier

For decades, car safety meant piling on steel. Lightweight materials flipped that logic. Advanced alloys and carbon fiber composites absorb impact forces like a boxer dodging punches—crumbling strategically to protect passengers. A modern car's aluminum roof can withstand twice the pressure of older steel models while weighing 40% less.

Even plastics play a role. High-strength polymers in bumpers and pillars flex on impact, reducing collision forces transferred to the cabin. Lightweight materials aren't about being delicate; they're about being smarter. Think of them as microscopic airbags woven into the car's DNA.

Cheaper Rides, Fewer Trade-Offs

Lighter cars sip fuel instead of chugging it. Every 10% reduction in weight boosts fuel efficiency by 6-8%. That means lightweight materials turn into real savings: Drive 15,000 miles a year, and you’ll visit the pump 2-3 fewer times annually. For electric vehicles (EVs), shedding pounds extends range—no costly battery upgrades needed.

Maintenance costs drop, too. Lightweight materials resist rust and corrosion, sparing you from pricey repairs in snowy states where road salt devours traditional frames. Even tire wear slows down, as lighter cars put less strain on rubber.

Greener Roads, Cleaner Conscience

Manufacturing lightweight materials does require energy, but the long-term payoff is staggering. A lighter car emits 5-7% less CO2 over its lifespan. For EVs, this compounds: Less weight means smaller batteries, which reduces lithium mining demands.

And recycling is getting clever. Today's aluminum-intensive cars are 90% recyclable, with reprocessed metal finding new life in everything from soda cans to airplanes. Lightweight materials are closing the loop on waste, turning old cars into future roadsters.

The Rise of Electric Vehicles (EVs)

EVs stand to gain the most from lightweight materials. Batteries are heavy, so reducing vehicle weight extends driving range without increasing battery size. Companies like Tesla use aluminum and glass composites to maximize efficiency, while startups like Rivian integrate lightweight magnesium components into their electric trucks. As battery technology improves, lightweight materials will become even more critical to making EVs affordable and practical for mainstream buyers.

Innovation in Every Component

From tires to interiors, lightweight materials are infiltrating every part of the car. Michelin’s “Vision” concept tire uses biodegradable rubber and 3D-printed recycled steel, cutting weight by 20%. Inside the cabin, flax fiber composites replace plastic in dashboards, reducing both weight and chemical emissions. These changes aren’t just about performance—they're about creating healthier, more sustainable driving environments.

Conclusion

As America transitions to a greener economy, lightweight materials are poised to play a starring role. They’re not just a trend—they're a necessity for meeting emission targets, improving safety, and keeping cars affordable. Whether you're buying a compact sedan or a heavy-duty truck, chances are lightweight materials are already working behind the scenes to make your ride smarter, safer, and more efficient.

The next time you hit the road, remember: the future of driving isn't heavier—it's lighter, stronger, and built to last.

Why Your Next Road Trip Needs a Co Pilot Named Intelligent Driving

As Americans gear up for holiday road trips or summer adventures, the idea of a stress-free journey often collides with reality: navigating unfamiliar routes, managing traffic, and staying alert during long drives. Enter Intelligent Driving—a suite of advanced technologies transforming cars into copilots that enhance safety, efficiency, and peace of mind. While fully autonomous vehicles remain a work in progress, today’s Intelligent Driving systems offer practical tools to elevate your travel experience.

No More Pushy Salesmen: How Live Commerce Makes Car Buying Transparent

For decades, buying a car in America has been synonymous with high-pressure sales tactics, hidden fees, and hours spent haggling in dealerships. But a quiet revolution is underway, driven by Automotive Live Commerce—a blend of live streaming, virtual reality (VR), and real-time interaction that’s transforming the car-buying experience. This shift empowers consumers with transparency, convenience, and control, all while eliminating the stress of traditional salesmanship.

How Electrification Transition Could Slash Your Monthly Car Bills

The global shift toward electric vehicles (EVs) isn’t just about reducing carbon footprints—it’s also reshaping how ordinary drivers manage their budgets. By swapping internal combustion engines for electric motors, the Electrification Transition promises to halve monthly car-related expenses. But how exactly does this happen? And how does Autonomous Driving factor into the equation?

Why Renting a Pickup Truck Could Save Your Thanksgiving

Thanksgiving in America is a time for family, feasting, and travel—but this year, it’s also a chance to rethink how we navigate the holiday chaos. With millions hitting the roads and skies despite weather challenges and public health advisories, shared mobility services offer a practical, cost-effective solution. Among these, renting a pickup truck stands out as a versatile option for tackling holiday tasks while minimizing stress and expense.

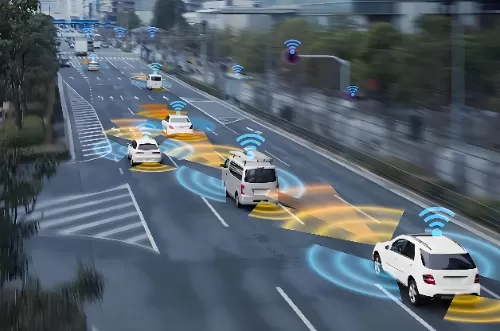

Are Self-Driving Cars Safer Than Humans

Picture this: It’s 8:15 a.m., and you’re balancing coffee, a conference call, and a backseat debate about why dinosaurs didn’t survive. Suddenly, a scooter cuts across three lanes. Your foot slams the brake—a reflex honed by years of driving. Now imagine your car handling that moment instead: no adrenaline, no panic, just sensors and algorithms reacting at lightning speed. This scenario plays out daily as autonomous driving quietly expands its reach. From Phoenix’s robotaxis to Shanghai’s self-parking sedans, vehicles without human drivers are no longer sci-fi. Yet a fundamental question lingers every time we see a car drive itself: Can machines truly outpace human skill behind the wheel? Autonomous driving technology promises safer roads, but the reality is far more nuanced than a simple “yes” or “no.”

How Lightweight Materials Are Making Cars Safer, Cheaper, and Greener

For decades, American drivers have prioritized power and space in their vehicles—but a quiet revolution is underway under the hood. Lightweight materials are reshaping the automotive industry, offering a triple threat of benefits: safer rides, lower costs, and a greener planet. While steel has long dominated car manufacturing, innovations in materials science are redefining what cars can be.

By:

Lorna

By:

Lorna